Choosing the right cutting tool can be the difference between a flawless, professional finish and a costly, frustrating mistake. When it comes to slicing through the toughest materials like concrete, granite, or tile, nothing beats the power and precision of a diamond blade. But with various options available, how do you know which one to pick? Understanding the main types of diamond blades is the first step toward project success.

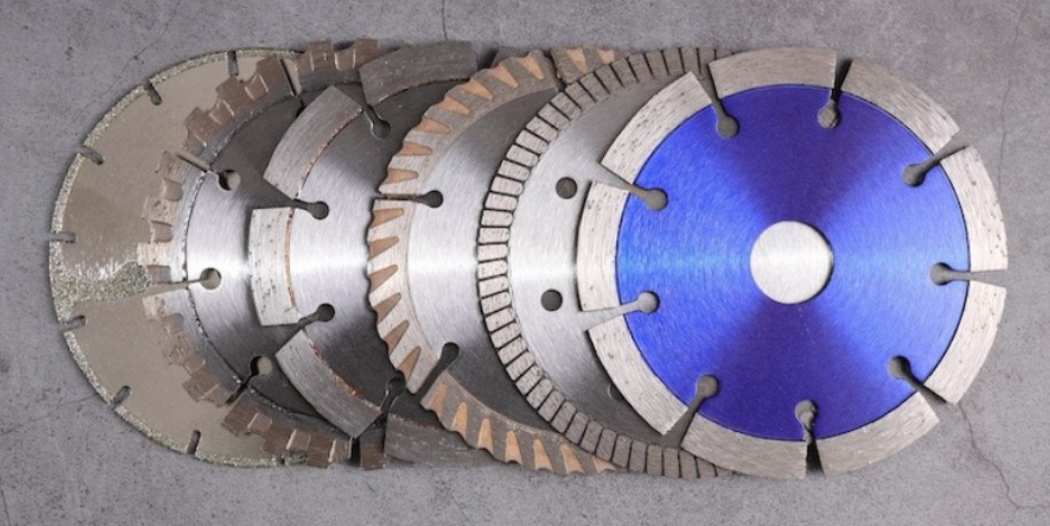

At their core, diamond blades are categorized by the design of their cutting edge, or rim. The three primary types you’ll encounter are:

- Segmented Rim Blades: Designed for aggressive, fast cutting of hard materials.

- Continuous Rim Blades: Built for clean, chip-free cuts in delicate materials.

- Turbo Rim Blades: A hybrid design offering a balance of speed and a smooth finish.

This comprehensive guide will break down each type, explain their specific applications, and provide the expert knowledge you need to select the perfect diamond cutting disc for your job, ensuring efficiency, safety, and superior results every time.

What Are Diamond Blades Made Of? (The Basics)

Contrary to what the name might suggest, a diamond blade isn’t a solid disc of diamond. Instead, its construction is a sophisticated blend of materials designed for durability and cutting efficiency. A diamond blade consists of two main parts: a circular steel core and a diamond-impregnated cutting rim. The steel core is a precision-engineered disc designed to spin true at high RPMs, featuring a central arbor hole to mount it onto a power tool.

The real magic happens at the rim. This section is made from a powdered metal mixture, called the bond or matrix, which has synthetic diamond crystals distributed throughout it. During manufacturing, this mixture is fused to the steel core through processes like sintering, laser welding, or brazing. As the blade cuts, the metal bond slowly erodes, exposing new, sharp diamond crystals to continue slicing through the material. The hardness of this bond is a critical factor, which we will explore later.

The 3 Main Types of Diamond Blades Explained

Navigating the world of diamond tools can seem complex, but it becomes much simpler when you understand the fundamental differences between the three main blade types. Each design—segmented, continuous, and turbo—is engineered with a specific purpose in mind, balancing speed, finish quality, and material compatibility. Answering the question “what are the three types of saw blades?” is key to any cutting project.

Your choice will directly impact the speed of your work, the cleanliness of the cut edge, and the overall lifespan of the blade. A blade designed for rough concrete cutting will perform poorly on delicate marble, and vice-versa. Let’s dive into the unique characteristics of each type to see where they shine.

Segmented Rim Blades: For Speed and Rough Cuts

A segmented rim diamond blade is easily identifiable by its distinctive slots, or gullets, that separate the cutting edge into sections. These gullets are not just for looks; they serve a crucial engineering purpose. They allow for significant air cooling, which makes segmented blades the top choice for dry cutting applications where water isn’t available or practical. Additionally, these slots help to eject cutting debris and slurry, allowing the blade to maintain aggressive cutting speed.

Because of their design, segmented blades deliver the fastest, most aggressive cut of the three types. However, this speed comes at the cost of finish quality, often leaving a rough or chipped edge. This makes them perfectly suited for jobs where the final appearance of the cut edge isn’t a primary concern.

- Best For: General purpose cutting of concrete (cured or reinforced), brick, block, pavers, and other masonry.

- Primary Advantage: High cutting speed and excellent cooling for dry use.

- Primary Disadvantage: Produces the roughest cut.

- Common Tools: Angle grinders, circular saws, and walk-behind concrete saws.

Continuous Rim Blades: For Precision and Fine Finishes

For projects demanding a flawless, chip-free finish, the continuous rim blade is the undisputed champion. As its name implies, this blade features a solid, uninterrupted diamond edge. This smooth design minimizes chipping and provides the cleanest possible cut, making it essential for work with fragile or high-end materials where aesthetics are paramount.

The lack of gullets means a continuous rim blade generates significant heat from friction. To counteract this and prevent the blade from warping or failing, it must be used with water. This makes it a dedicated wet cutting blade. The water not only cools the blade but also suppresses harmful dust and flushes away debris for an even smoother cutting action.

- Best For: Delicate and brittle materials like ceramic tile, porcelain, glass, marble, and granite.

- Primary Advantage: Delivers an exceptionally clean, chip-free finish.

- Primary Disadvantage: Slower cutting speed and requires water for cooling.

- Common Tools: Tile saws and wet-cutting angle grinders.

Turbo Rim Blades: The Best of Both Worlds

What if you need a faster cut than a continuous rim blade but a cleaner finish than a segmented one? Enter the turbo blades. A turbo rim blade is a clever hybrid, featuring a continuous rim that is serrated or crenelated. This design incorporates small cooling holes or indentations along the rim, which help with heat dissipation and debris removal, mimicking the function of a segmented blade’s gullets but on a smaller scale.

This unique construction allows turbo rim diamond blade applications to be incredibly versatile. It offers a great balance, providing a much faster cut than a continuous rim blade while leaving a significantly smoother finish than a segmented blade. Many turbo blades are designed for both wet and dry cutting, making them a popular, all-around choice for contractors and serious DIYers who work with a variety of materials.

- Best For: A wide range of materials including stone, masonry, concrete, and granite.

- Primary Advantage: A versatile combination of fast cutting and a relatively smooth finish.

- Primary Disadvantage: Not as fast as a segmented blade or as clean-cutting as a continuous rim blade.

- Common Tools: Angle grinders, circular saws, and tile saws.

How to Choose the Right Diamond Blade for Your Material (Comparison Table)

To simplify your decision, we’ve created a detailed comparison table. Use this chart to quickly match the blade type to your specific material and project requirements, answering the common question, “what are diamond blades used for?” in a clear, visual format.

| Blade Type | Best For Materials | Cut Speed | Finish Quality | Ideal Cutting Method |

|---|---|---|---|---|

| Segmented Rim | Concrete, Brick, Block, Pavers, Masonry | Very Fast | Rough | Dry or Wet |

| Continuous Rim | Porcelain, Ceramic Tile, Marble, Granite, Glass | Slow | Excellent (Chip-Free) | Wet Only |

| Turbo Rim | General Purpose Stone, Concrete, Granite, Masonry | Fast | Good/Smooth | Dry or Wet |

Wet Cutting vs. Dry Cutting: Which Method to Use?

The choice between wet and dry cutting is determined by your blade, your material, and your work environment. Each method has distinct advantages and is suited for different scenarios. Using the wrong method can not only damage the blade and your workpiece but also pose significant safety risks.

Advantages of Wet Cutting

Wet cutting involves using a steady stream of water to flow over the blade and cutting surface. This is the preferred method for most professional applications. The primary benefits include:

- Superior Cooling: Water is the most effective way to prevent a diamond blade from overheating, which dramatically extends its life and prevents warping.

- Dust Suppression: It virtually eliminates airborne silica dust, a major health hazard in construction. This creates a safer working environment.

- Smoother Finish: The water acts as a lubricant and flushes away cutting debris, resulting in a cleaner cut with less chipping.

- Blade Requirement: It is mandatory for continuous rim blades and highly recommended for turbo and segmented blades to maximize their lifespan.

When to Use Dry Cutting

Dry cutting is done without water and is valued for its convenience. It’s suitable for job sites where water is inaccessible or when working with power tools not designed for wet use. However, it comes with important caveats:

- Convenience: There’s no need for a water source or the messy slurry cleanup that follows wet cutting.

- Heat Buildup: Without water, the blade and material heat up rapidly. To manage this, dry cutting should be done in shallow passes or short, intermittent cuts, allowing the blade to air-cool between passes.

- Dust Hazard: Dry cutting creates a large amount of hazardous dust. A respirator, safety glasses, and proper ventilation are non-negotiable safety requirements.

- Blade Compatibility: Only blades specifically designed for dry cutting (typically segmented and some turbo blades) should be used. Using a wet-only blade dry will destroy it quickly.

Matching Diamond Blades to Your Power Tool

Selecting the right blade type is only half the battle; you must also ensure it’s compatible with your power tool. An improper match is inefficient and extremely dangerous. Pay close attention to three key specifications: blade diameter, arbor hole size, and the maximum RPM rating.

A small diamond blade for an angle grinder will typically be 4 to 7 inches in diameter, while large walk-behind saws for concrete cutting can use blades that are 14 inches or larger. The blade’s arbor hole must perfectly match the saw’s arbor or mounting flange. Finally, the blade’s maximum RPM rating (printed on the blade) must be higher than the maximum RPM of your tool. Exceeding the blade’s RPM limit can cause it to shatter during operation.